I acquired my dad’s 1984 Simplicity 7790 diesel about 5 years ago. My dad used this tractor for everything for 20yrs and originally bought it from my grandfather back in the 1986. I have a ton of attachments for this thing including a cool front dump bucket. Sadly, when I received the tractor it was pretty worn out. The engine smoked really bad and leaked fuel everywhere. It was very hard to start and was unusable. The engine is a Lombardini 10LD400-2 two cylinder 18.5hp diesel engine. It’s air cooled and is a real work horse. The only bad things are that it is loud and smells. I however think it is a neat tractor and like driving it. This is identical to the Allis Chalmers 920 Diesel. All attachments from the Simplicity 7000 series frame tractors fit this tractor and many tractor parts (except engine parts) are interchangeable as well.

I spent the next month rebuilding the engine and getting it back into good working condition. All the parts had to be imported from Italy which cost a lot and takes several weeks.

I bought all the engine parts from here: http://powersupplyequipment.net/

They deal with Lombardini parts and were able to get me everything I needed. The total cost for the rebuild was $582 which included a gasket set, valves, bearings, and piston ring set. I did not need pistons or jugs since they were within factory specs.

Update 12-22-14– I guess powersupplyequipment.net no longer supplies the Lombardi engine parts.

Kholer now owns Lombardini. Parts might be available with them as well. There are also other parts that fit this engine perfectly. Rings are the same as a Mazda 626 Diesel, part # 2M4210.

The engine leaked everywhere and had grease and dirt all over it. Debris collects under the cowling and prevents air from cooling cylinder heads. This will cause the cylinders to overheat and destroy the rings. After every use you need to blow compressed air through the engine cowlings and blow all the grass and crap out of there.

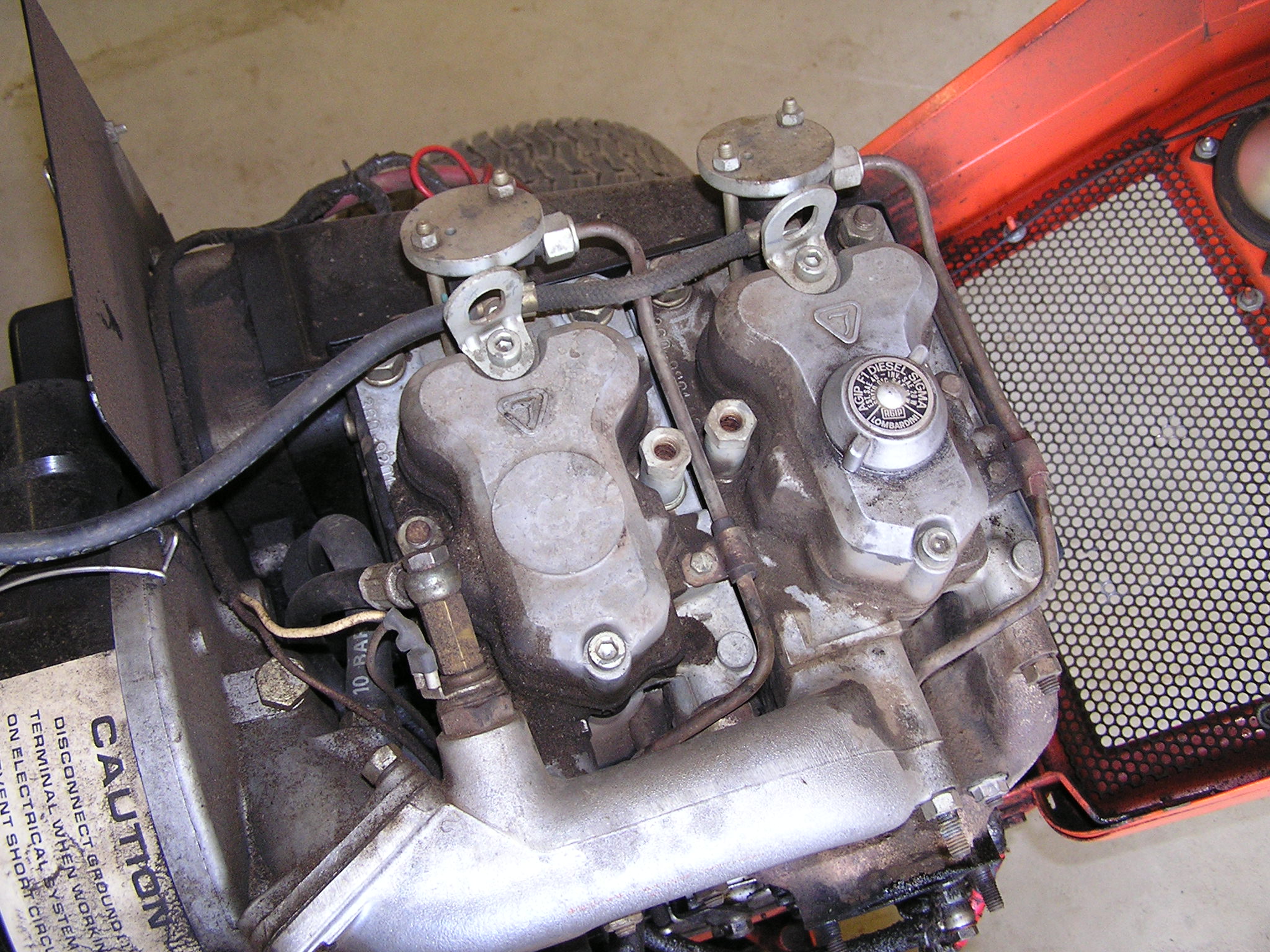

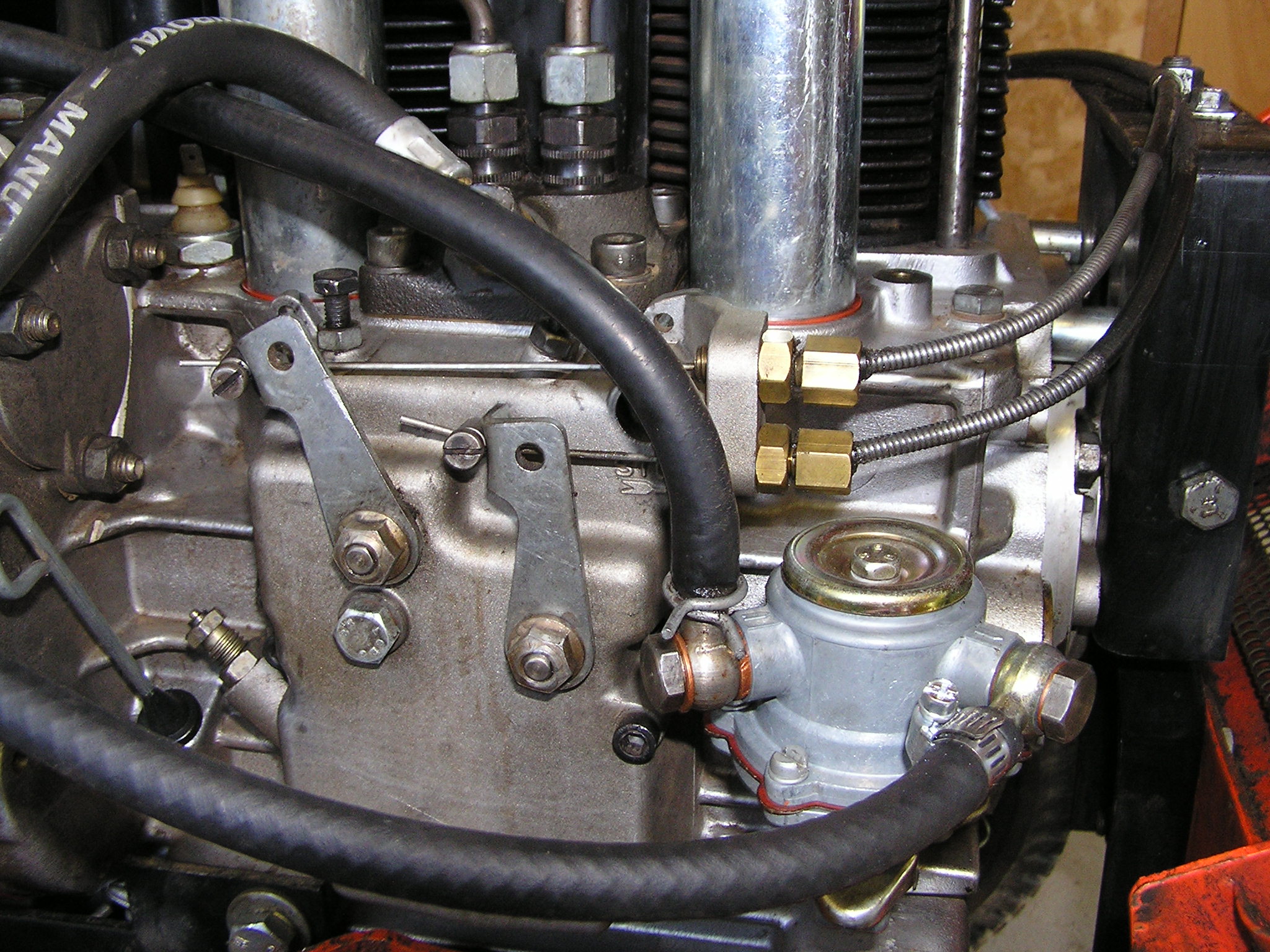

The first thing I did was remove all the cowlings. Next unbolt the intake and exhaust manifolds and carefully unscrew the injector lines. The engine is a really simple one to work on and has nothing special to worry about other than its a diesel. I plugged the injector ports with a clean rag to prevent dirt from falling in there.

Examining my valves revealed a bad sign. You can see oil everywhere which came from bad rings and leaky valves. I needed to order a complete gasket kit, valves, and rings for this engine so far. I also bought new con rod bearings as well.

I bought this service manual by Clymer for this engine and I am not going to go into great detail on how perform every detail to an engine rebuild.

This book completely covers the Lombardini 10LD400-2 engine and I highly recommend it if you want to get your engine running. I recommend that you have some mechanical experience before you attempt anything like this. I cleaned everything and installed new valves and had the valve seats ground. I also honed the cylinder jugs and installed new rings and bearings. I took apart the injectors and cleaned them very carefully. I had to replace all my fuel lines and a small copper gasket that was inside the fuel injector right under the nipple.

The engine is all cleaned up and put back together. The manifolds are not on there yet but they will be shortly.

The injector pump is a very delicate device. Do not dismantle this unless you know what you are doing.

The compression on this engine was much higher after the rebuild and my starter could not turn it over. I took my starter to a local starter repair shop and it had it repaired. $100 later I had a rebuilt starter. The tractor now starts easily and even in the winter it has little difficulty starting. The rebuild was completely worth it. I was amazed at the power that this little garden tractor has. I mainly snow blow and rototiller my garden with it and have never had any problems so far. I’ll try to post some video of it running soon and some pics of the attachments.

Shown above is the cool dump bucket.

Update 01-26-14

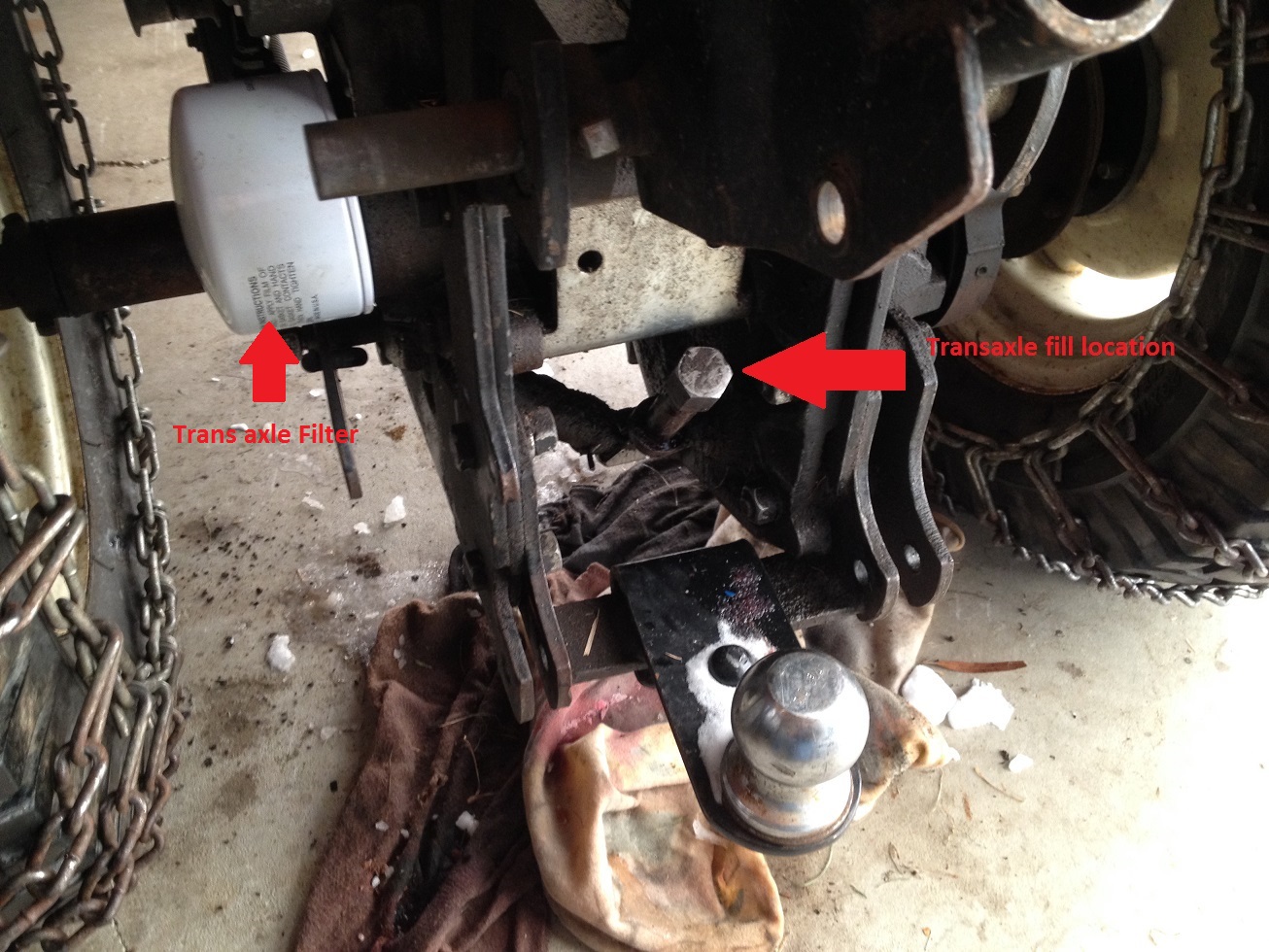

Had some trouble with the trans-axle this week. Winter is blasting us here in Michigan so I have been using the snow blower attachment every week. The tractor started to have trouble moving and eventually stopped moving unless I held the hydraulic lift lever open. Honestly I have never touched the trans axle or changed fluid. Its probably original since my dad never remembers changing it either. Anyway, I ended up changing the fluid and filter. The fluid was dark red and I only drained about 1.5 quarts out of it. I used Valvoline ATF type FA transmission oil to refill and added 2.5 quarts. Wow this thing moves like new now. I must have slowly lost some response over time because its never been this responsive. I’ll be changing the fluid every 400 hrs like the manual states now. I used the replacement simplicity filter which was expensive. Does anyone have a Napa cross reference for a non brand filter? Has to be 25 micron. I also checked the bevel gear box and ended up adding some 80-90 weight oil to that. I’ll take the old filter up town and see if I can get a Napa replacement.

Update 01-27-15

I upgraded the snow blower skids to a new heavy duty “Armor Skid” set from Home Depot. Welded from 1/8 inch and 1/4 inch steel. My old ones were getting worn away (see below). One of my skids was less than 50% and my snow blower was getting hard to push because it was dragging on the ground.

The new ones work great and I painted them “Chevy Orange” which is incredibly close to simplicity orange.

Update 03-03-16

I broke the drive shaft today while I was snow blowing. I knew the couplings were getting old and I hit a small seam in the concrete driveway that jolted the tractor enough to break the coupling. What a disaster. The shaft banged all around and twisted itself into a pretzel. I had to cut it out with a torch.

I also busted a screw off in the engine mount. Gotta get that out.

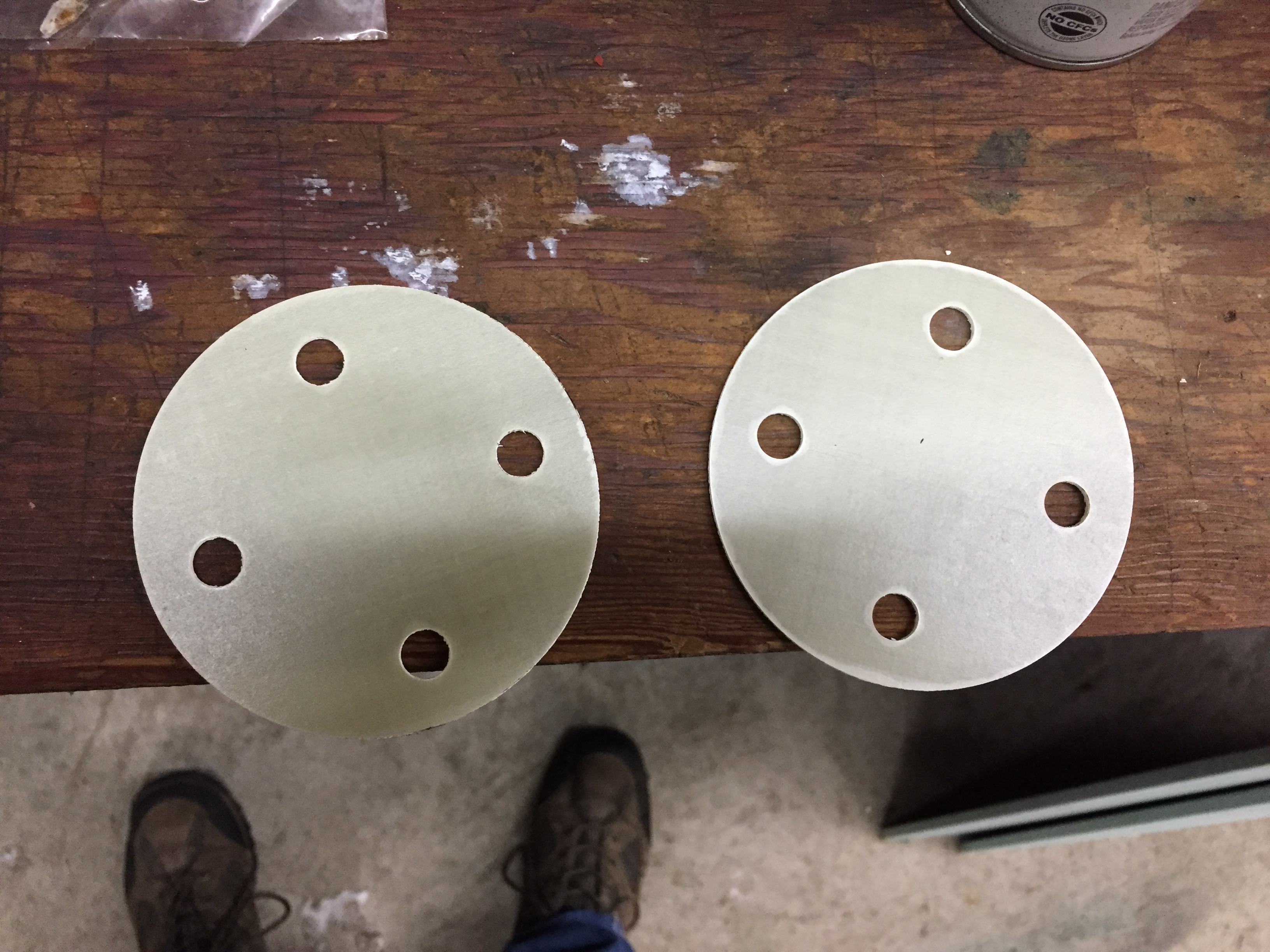

Busted up couplings. The 2nd coupling exploded into a million pieces. These are kind of expensive and I did not want to buy them. I made a set myself out of G10 (same material circuit boards are made of).

Getting the new shaft into the tractor is not too bad. I had to lower one end of the hydraulic cylinder and remove one bracket that was in they way. It took about 2 hrs to make this repair.

Drive shafts are expensive ($150+). I made mine easily with 1″ bar stock. I ground the original ends off and welded them onto the new shaft. Total cost for the new shaft was about $5 for the 3ft piece of cold rolled steel from the local steel supplier. The new drive shaft measures 20 1/4 inch exactly if you want to make one.

New drive shaft shown below.

The couplings can be made or purchased. Here is the drawing I made for the couplings:

Drawing of Drive Shaft Coupling

I made mine on my CNC mill but you can make them with a drill press and a band saw easily. Just print the drawing to scale and tape it on your sheet of G10. Drill the holes and trace the circle on with a pencil. Cut it out with a band saw or jig saw.

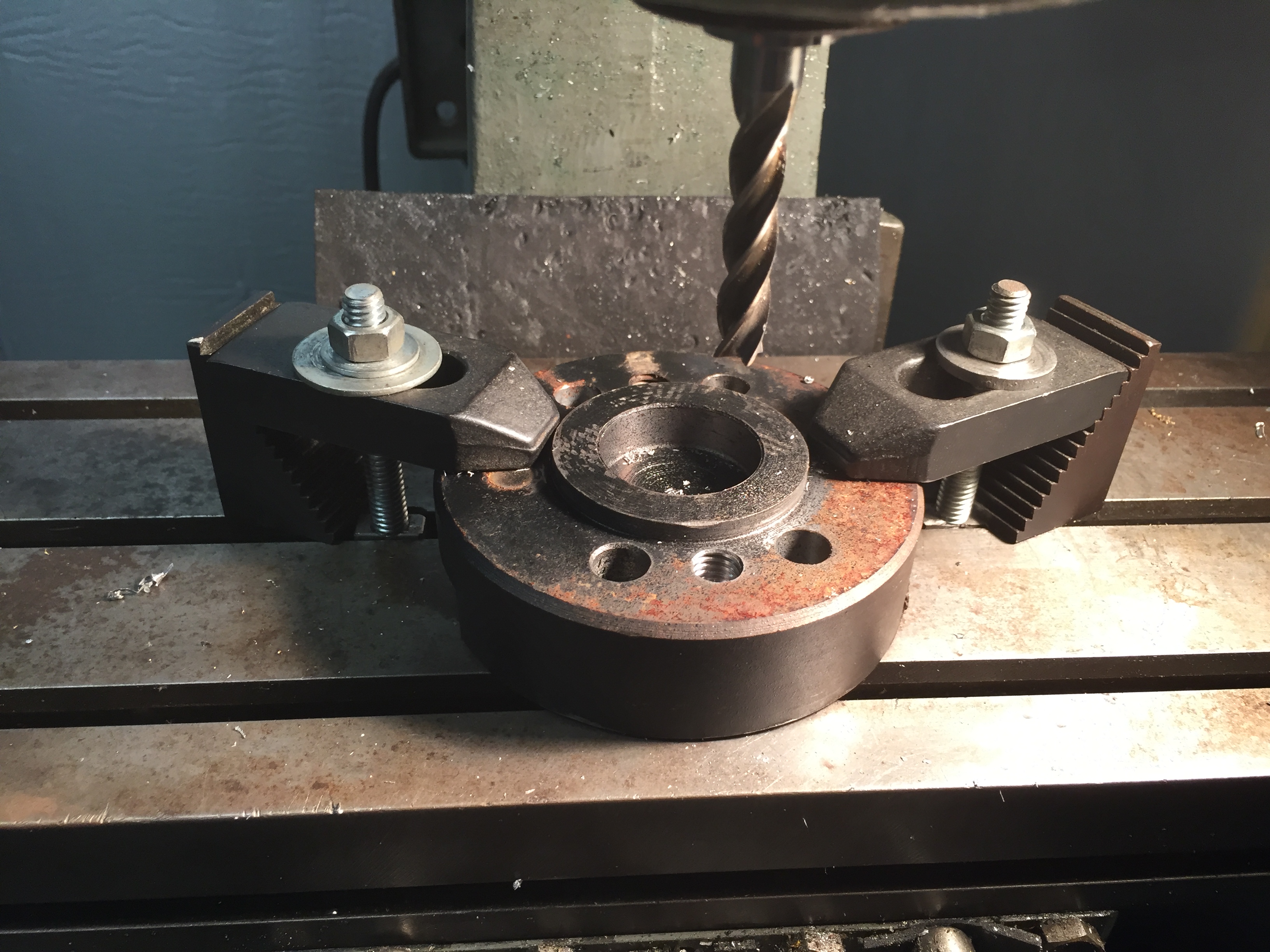

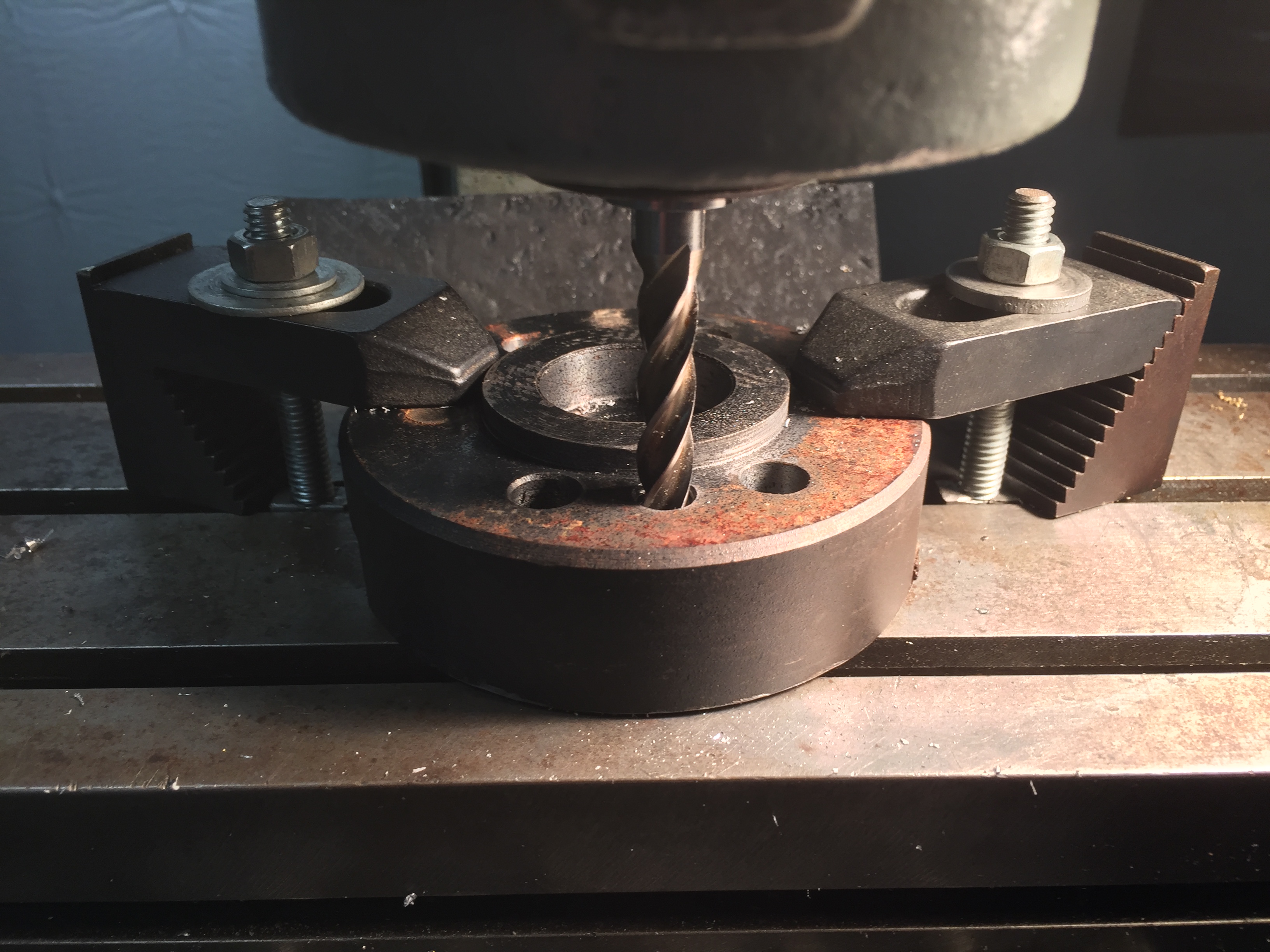

Now I need to get that broken screw out of the engine drive shaft hub. I drilled it out from the back with a end mill.

Got it out. I ran a 3/8-16 tap in the hole to clean it out.

Here is the new shaft and the new coupling. No problems now.

Made some spare drive shafts for later….

Update 12-04-16

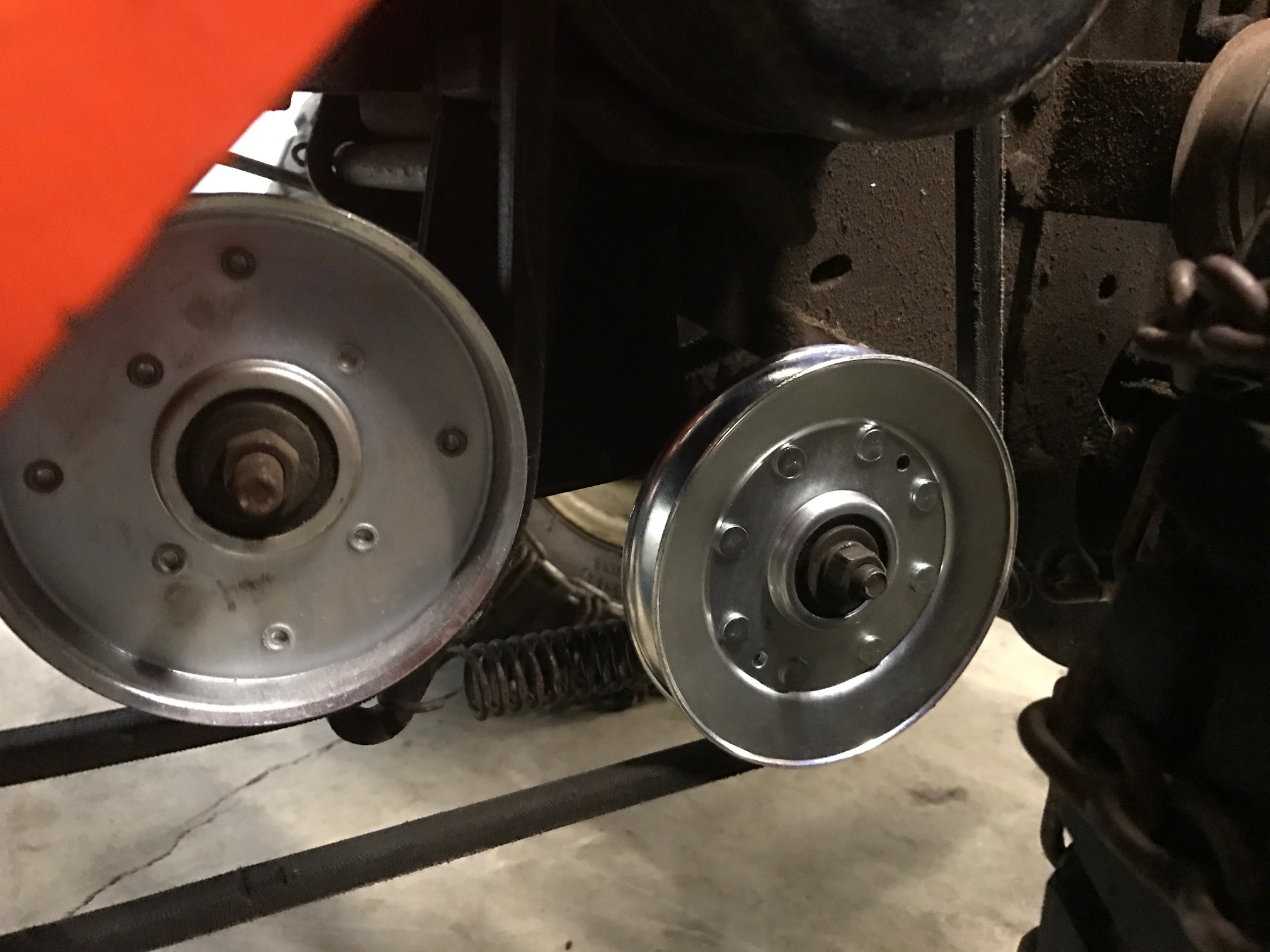

Getting ready for winter and I found one of my PTO pulleys had a failed bearing. Stupid thing cost $45 from Simplicity dealer and is an odd size. I will be looking at Grainger or some other online store to find an equivalent for any other pulleys that fail.

Don’t forget to press out the center bushing on the old pulley. It is needed for the new pulley. I just used a socket and small hammer to tap it out.

All done installed. Good for winter.

Update 07-30-17

Here are some pics of the Rototiller attachment. I use it all summer on my garden.

Update 10-18-18

I finally found an original SNOW CAB for my Simplicity. There will be no more snow in my face this winter. I don’t think its original to my size tractor but its for the 7100 series SNOW CAB MODEL # 1667343 or 1690496. I uploaded the install manual for this snow cab in the links below. The cab is in pretty good shape for its age and I paid $150 for it used off craigslist. It fits perfect so don’t worry if you find one not specific to the 7790. Get one for the 7100 or 7200 series garden tractors and it will fit the 7790. This cab is heavy canvas with clear vinyl windows wrapped around a frame made of steel rod . The roof is a hard top made of fiberglass and the doors open and latch on both sides. Its quite a nice cab and I’ll up load videos this winter when I use it.

Installation was pretty simple but I had to add 4 mounting holes to my tractor and make two spacers for the dash board. I think the 7100 series has a slightly different tractor frame than my 7900. The cab mounts to the dashboard existing screw holes (remove the two top screws and save them). I added 2 inch long spacers for these two locations since the cab frame was too high. I made them out of 0.750″ round nylon plastic I had laying around. I drilled them out for a 1/4-20 bolt.

Spacers shown above

The spacers mount under the frame to the dashboard as shown (shown above)

All the other mounting locations were fine. I drilled a few holes in the foot rests and I had two drill two holes behind the seat on the fenders.

Above you can see where the cab mounts to the foot rest. I drilled two holes per side.

Behind the seat I drilled two holes for the rear mount on the fender (shown above) I used heavy duty rubber spacer between every mount so I would not scratch my paint.

The other upgrade I wanted to do was to add some lights to the cab. The front headlights are half blocked by the snow blower so I wanted some high mounted lights near the roof. I bought some cheap off road LED flood lights off Amazon for $13 a pair. I bought 2 pair and mounted two lights facing forward and one light facing backwards. I used the same wire for the rear mounted fender light and just added a plug for the cab. I ran wires inside the cab and added some switches. I also added a amber blinking LED safety light to the top for when I am on the county road snow blowing the end of my driveway. Its high traffic and I don’t want to get hit. I did not drill any holes for any of the light mounts. I used the existing cab mounting bolts and holes for the light brackets.

Off road lights I mounted (shown above). Each light draws 1 AMP. They are super bright and I am very happy with them.

https://www.amazon.com/gp/product/B00G620ZVU/ref=oh_aui_detailpage_o07_s00?ie=UTF8&psc=1

Safety Light Shown above. Draws 0.2 AMPS

https://www.amazon.com/gp/product/B06XRCCZC8/ref=oh_aui_detailpage_o07_s00?ie=UTF8&psc=1

I was worried about all the extra amp load on the electrical system and I don’t know the rated output of the Lombardini alternator. I did not want to risk burning it up so I swapped out all the old OEM bulbs or low amp LED bulbs. Each OEM headlight draws 3 Amps each bulb. The new LED replacement draws about 1 AMP each bulb.

Above the OEM bulb is on the left and the LED is on the right. The LED bulb is solid glass and is 2x as heavy as the OEM bulb. Link is below for the ones I bought (3000k color)

https://www.amazon.com/gp/product/B06XWWB5LM/ref=oh_aui_detailpage_o08_s00?ie=UTF8&psc=1

The LED light is shown above on the left. The original bulb is on the right. Honestly I could not tell the difference. The LED light is very bright and works just as well as the original. I still kept the original lights just in case I wanted to convert them back.

Update 11-07-22

I installed the snowblower today while getting everything ready for winter. The snowblower belt was really bad with cracks and chunks of belt missing so I replaced it. The belt is 1/2″ x 146″ and I used a Gates A144. It lasted 20 yrs so I guess its time for a new one.

Fluids and Misc Info I use:

Engine Oil : Rotella T 30Wt (also T1 works)

Transaxle Oil: Valvoline ATF type FA transmission fluid (2.5 qts)

Gear Box Oil: 80-90Wt Gear Oil

Fuel: Off Road Diesel. I also have used 100’s of gallons of #2 Heating oil. No Problems.

Battery: AC-Delco 34PG Group 34 Size is the biggest that will fit.

Paint: Dupli-Color “Chevrolet Orange” part # DE1620. Can be bought at Advanced Auto.

Simplicity 7790 Operators Manual

Simplicity 7790 Parts Manual

Simplicity 7790 Snow Blower Attachment

Engine Service Manual PDF

Simplicity 7100 Snow Cab

Drawing of Drive Shaft Coupling

Engine Service Manual I used:

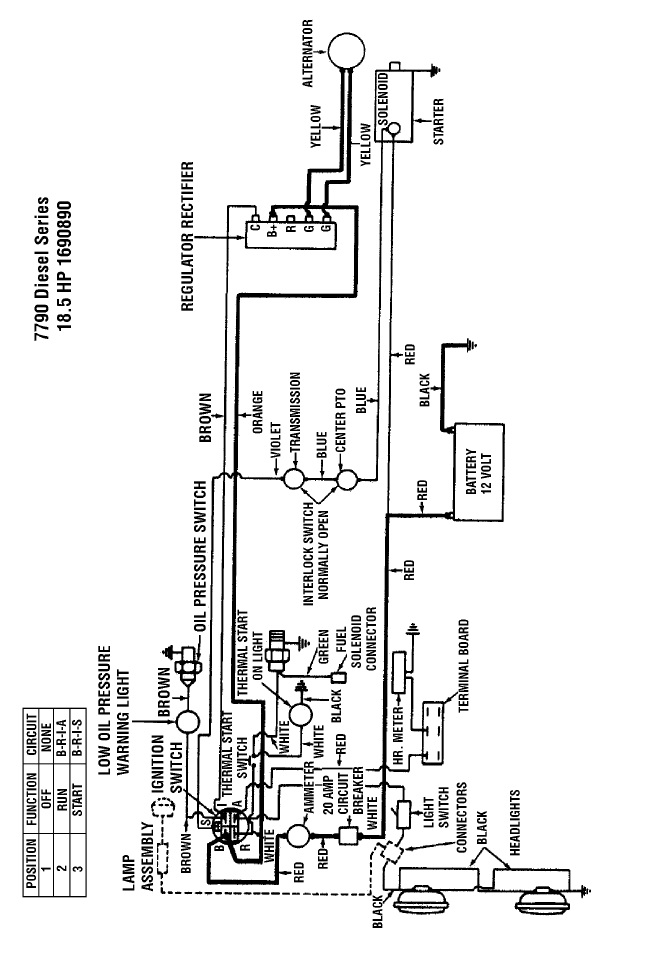

I also have an electrical schematic for the alternator if interested:

I’ve got a dear friend who is rebuilding a 7790, he has a a lot of mechanical knowledge, but not very computer saavy, I’m trying to find a service manual on PDF so I can print it into a binder for him as a present, Let me know if you can help. Thank you very much, Alain

I have a 7790 also same serial number Trying to find an intake heater for it And the fuel solenoid Is there something that will retrofit that Having hard time trying to find it 563 387 7697 Andy thanks

I found it and will post it shortly for you.

Wondering if you could tell me where I could find an intake heater and fuel solenoid for my thermal start on my 7790 lombardini 10LD400-2 my cell563 487 7697 Thanks

Good afternoon have 7790 simplicity diesel and intake heater and fuel solenoid need to be replaced is there any place to get them I tried lots of places come up empty any info would be great replied a while ago and mistyped my cell # 563 387 7697 thanks

I have no info on a replacement solenoid. Mine has not worked since I have owned it. Mine starts just fine without it. In the winter I use a heater blowing on the engine for 10 minutes. Starts right up. Are you have trouble starting yours?

Can I get the service manual in PDF?

Need to fix my motor.

I have an Allis Chalmers/Simplicity unit that is identical to the one described in your website (10LD400 Engine). I am curious as to where you purchased parts for the Lombardini Engine. I have dealt with a company called Hoover Diesel in PA but would be interested in any other places that might sell parts. Thanks for your help.

Chuck Davis

http://powersupplyequipment.com/

I bought all my parts from here. They had to order them from Lombardini in Italy. It took a few weeks to get my parts.

mine will not come up to full RPM at full throtle.

has always started OK at full throtle until now

Fuel Pump has been suggested.

What do you think, and if so what’s the best way to either rebuild of replace the fuel pump

You should try mowing with it.

The Simplicity mowing deck is the best I’ve ever used!!!!

IT can nearly bush hog to a finish cut in one pass.

I mow our field with the cousin to this machine, Allis Chalmers 920, 48″ deck.

I can take 8 to 12″ growth to >1″ cut in one pass.

I’ve got to ring mine this winter and fix a fuel leak around the injector pump.

I use the mower deck for exactly that. When the grass gets too tall for my other mower, I get the old Simplicity out which mows it with ease! I use the tractor for tillering the garden and snow blowing in the winter. it does an awesome job.

I need to know what type of oil to use in my 7790 Simplicity tractor. I got it used and had the injectors and pump rebuilt.Now the engine cranks and runs fine. The oil in the drive pump was filled with water, so i drained it, now with new filter, i need to know what kind of hydr. oil to put in the pump.

if you can tell me, send me a email.

Thanks Jay

Hello Mike… Great Job. Would you please post some pictures of the attachments, especially the front dump bucket? Thanks…

Jay,

I use the original Ford ATF transmission fluid in my hydro unit. I have never had a problem.

I’ll get some pictures of the attachments.

I love my Gravely rider but hate the problems that ethanol fuel involves nowdays. In your opinion would the output shaft on the 7790 diesel motor be similiar to other small gas engines? I have an onan b43 but Gravelys also came with Kohler singles and twins– thanks!

Great tractor! I have 7112 with a 18hp Kohler Mag, but just picked up the 7790 to play with a fix up. Hopefully mine will come out as well as yours. Was your leaks mostly oil or was it also fuel? Seems like I have a lot of fuel leaks. Also, did you get the Gasket/O-ring kit (~$140) and if so, did it have everything you needed as far as gaskets?

Do you still have the 7790? Could you send a pic of the connections by the voltage regulator, under the rubber boot? I have a red wire from the harness side with 2 yellow wires, the red is clipped off, not sure if it is suppose to clip to the regulator. Drawing of wiring diagram would be helpful also please. Thanks

hey i got a 10LD400-2 but just the motor i picked it up with a broken connecting rod and im going to replace it it was the only thing thats wrong with it but i was wondering where i might be able to find a wiring diagram for it i would like to get it running again

I recently acquired a really nice 7790 and I am working with some of the wiring (the intake heater) and I am also looking for a wiring schematic on this awesome machine. The charging system is currently not charging and the intake heater is not hooked up so I am working on these few issues to get it going for the winter. Any help would be greatly appreciated!! thanks for the pics and information on your build.

Unfortunately I do not have a wiring diagram for the tractor. If anyone ever finds one please send it to me and I will post it on this site for everyone to have.

If your system is not charging there are two items you need to check. 1st is the rectifier that is mounted to the engine. Make sure the AC voltage output from the alternator is getting to it. If the AC stops there, you have a bad rectifier. If you do not get any AC voltage from the alternator, you need to pull it off and have it checked for a broken wire and re-round if necessary.

Thanks for the info, The wires were rotted off to the fuel selenoid that feeds fuel to the intake heater but with the great electrical skills that the electrical engineers have where I work they were able to fix it. I figured out quite a bit of the wiring from your pics and and just tracing wires. I also found that the red wire was broken coming from the alternator to the regulator. Now I am waiting for my new ign switch and rebuilt starter to get here and I should be back in business for the most part. I need to figure out why it was surging when it was running (jsut picked up a new fuel filter so I will try that first) and I also need to put in some new motor isolators as I can rock the engine back and forth in the chassis. I have located a set of AG tires with chains and weights then I need to find a blade and I will be off plowing wisconsin snow. Thanks again for the info!

well i finally got the starter back from being rebuilt $110, bought some new engine mounts and cleaned up the engine. got my ag tires with weights and chains on and am in the process of putting things back together. I also finally got a legit lombardini service manual.

Hey that’s great I am using one of that till 2009 it’s really great and hard working. It is really long lasting.

Great info on theses tractors !!! I recently bought one at a sale. Like anything, it came with issues lol. Crankcase is getting fuel in it. First thing that I notice was the preheat fuel was by passed. After I got it running for few mins it started to puke oil/fuel mix out of back near flywheel.So i pull both return lines off and there is no fuel returning when running at a low speed. Guess my next set is to clean injectors.Any ideas? Best way to contact me is my cell.814 319 3500

Clean Injectors but still the same. Any ideas?

Thanks Paul for the response.

Mike, Awesome build post. I am looking for a tractor for my place here in New England. A diesel like this would be just the ting and I am thankfuly mechanicaly inclined. Do you think the 7790 is powerful enough to throw wet snow? We get alot of that here in Ma. especially as I am on the coast. I am impressed with the work you’ve done. Thanks.

Mike… I shot you an email re: the 7790 snowthrower. I am having trouble mounting the snow attachment. Can you help? I included pictures in the email.

great post I have a CME site dumper 2.5ton with a 9LD561-2 motor,been looking for works manual for ? how long,and elect diag BONUS,can now start to pull down motor and set up wiring as in your tractor,should work!,

I bought a 7790 this past Jan 2014. Had only 206 hours. Thanks for the useful info on this site. Beginning to baseline the tractor. It’s a great mower & snowblower.

I have a 7790. Bought used. Runs great but recently developed a fuel leak. Appears to be coming from a fixture that the fuel line goes to. Is that where the copper gasket goes that you referenced at the nipple? If so is it much of a chore to install? Limited mechanical knowledge!!!!! Appreciate any help you can give me!!!! Thank you Jack Stephenson Monroeville, In

It can be fixed in a Saturday afternoon. You have to take the exhaust manifold off if I remember correct. That will give you access to take the steel nipple off and the copper gasket is right under it. I posted a picture of it in a tractor forum once. http://www.mytractorforum.com/showthread.php?t=54215&page=2 I found it.

how do you mick the head gasket for this lombardini? I took the heads off and I called the fellow for the head gaskets he told me I have to mick the head gasket. how do I do because I took the head gaskets out of the head and don’t know witch ones go where.if you can tell me how that would be a lot of help. thank you Bucky

“MIC the gasket” means he wants to know how thick the copper head gaskets are. Use a set of calipers or micrometers to measure. I just use a good pair calipers. Yeah if you don’t remember which one goes where that could be a problem. Measure them first because they might be the same (hopefully).

is there anyway to tell. I do know the gaskets are not the same.is there anyway I can tell which head goes where?

Sorry I don’t know of a way to identify them after dis assembly. I marked mine with a punch when I took them off. One dot and two dots for #1 and #2 cylinder.

Mike,

Hoping you could help. I too have a 7790 diesel my father bought a lot of yrs ago. I have been using for about 12 yrs now. never replaced anything but belts and blades. yesterday engine seemed to lose power and smoke a little. noticed oil coming down on side of engine on the side with all fuel lines. I’d rather fix this one than buy a throw away mower. I am thinking maybe rings. there was little smoke. But tractor will still start and pull. Just with loss of power.

Is it leaking engine oil or diesel fuel?

Mike,

Sorry for late reply. Seems to be oil seal on front of engine. Seal looks as though its been run hot and has some sort of metal on it.

Also I Gave the equipment supply a call but they say they no longer have access to these parts. I have pulled the deck and am in process of hoping for a miracle to make it run again. I did speak with one company in Greenville sc who said they could order parts but they are extremely expensive and take forever to get back. I did notice you stated that some other pistons from a diesel car would fit the machine would you please give me yr make and model.

Or pistons rings? It may have overheated even though I keep plastic guard areas clean.

Oh and Thanks for your help

Mike,

Thanks for the detailed blog, my decision to purchase a 7790 was based in large part on what you published. Mine was missing the fuel tank and battery, apparently they were stolen while it was parked in the back yard of the old man who sold it to me. It only has 179 hours on it and it appears that it’s in good shape, I expect that it should run well after thorough maintenance. My question is: do you know of a source for a replacement fuel tank, and what is the standard size of the battery. My brother owns an auto shop and I can order the battery at wholesale price, but not sure what size. Thanks again!

Battery Size: I buy AC-Delco 34PG from local Chevy Dealer. Size is Group 34. Nothing bigger will fit.

Getting parts for these tractors is getting difficult. For a gas tank I would check out Ebay.

http://stores.ebay.com/Joes-Outdoor-Power

I have seen this guy sell 7790 parts once in a while. He owns a huge tractor junk yard. It might be worth it to give him a call. He also can cross reference the tank.

Thanks Mike, I located a replacement fuel tank through Small Engine Parts Warehouse (sepw.com if im not mistaken), apparently its the same tank that came on the gas model but will require adding the fuel return line. Im not trying to turn your blog into a forum, but for as much help as it has provided me I figured I would pass on the helpful info. Thanks again!

No worries. I really enjoy all the comments.

Mike,

Found the front oil seal was leaking. I had to match it up to find one to work. It no longer leaks oil but has developed a knock at bottom of engine. I suspect bearings. I found a place that has bearings as well as oversized bearings. I will be removing pan this weekend. I am removing the crank as well to give it a good looking over. I was wondering if someone has a gasket set for this machine. If not I can make one for the oil pan.

My 7790 10LD400-2B1 runs but is stuck full throttle and I’m not sure why. Cable is not broke Lol any ideas as to why?

If the cable is functioning normally then you have a broken injection pump. The lever inside that closes off the fuel flow is broken or has come loose. I have never been inside the pump that far so I could not tell you exactly.

I have a allis chalmers 920 with the 10ld400-2 diesel that I need to rebuild does the Clymer Manual cover overhaul and where do I get one . Any help on the manual and where to get parts would be greatly appreciated as Most Kohler dealers are lost when it comes knowing about this engine

just bought a simplicity 7790 throttle is stuck wide open and you can’t shut it down or off any ideas PLEASE HELP

Mike please help. Any idea where I can get this .50 bearing ED0016110530-S, that’s the kohler number. the lombardini number is 1611.053. I have all other parts to get my machine back together except the main bearing. I have googled and ordered from more than six companies online that show they have it, only to be refunded when it shows discontinued on the kohler number. I took it to engine machine shop who said they could not make it. I am a loss.

Need starter motor for Lombardini 10 LD 400-2/B1 engine….. s/n 2503229.

I am looking for a snow blower for my 7790 tractor, does anyone know what simplicity model number snow blower will fit this tractor?

Any snowblower with the front hitch will work.

3300, 3400, 7000 series are all the same. My dad had a old landlord from the 1960’s and that snowblower fit my 7790 as well. I see them on craigslist once in a while.

John Wood – Where does the bearing go? Is it a brass bearing or a ball bearing?

Model number for the 36″ Blower: 1690547

Model number for the 42″ Blower: 1690548

I’m looking at a 7790, but the terrain where I live is probably a much steeper than 15° and I’m concealed that it won’t have enough power to get up the hill.

It does come with the clamp on wheels to make it a dually.

Amy thought our concealed?

Power is a non issue with this tractor. It will spin the wheels no matter what. What I find limiting is the weight of the tractor. It will spin the tires on a steep incline or if pulling something really heavy. My tires are just turf tires so that might be the problem. I leave my winter chains on year round and I have no more issues pulling or slipping on steep inclines. I have a belly blade for grading the driveway and it works like a charm with the tire chains.

Just a thought on diesel smoke, someone in the States conveted his big rig to run on one of those homade HHO generators that run on water with 25% sodium hydroxide and now has a zero emission tractor trailer! His needed 200 ss plates, but yours could use a 4″ pvc pipe about 16″ tall to produce enough hydrogen and oxygen jto run that diesel and give you tons of torque…maybe not tons, but plenty. But I don’t know how you convert the engine. You can see how to make one on YouTube, and they are impressive. From welding to powering a generator and heating a house with water and zero emmisions, it’s a great idea. There is a large pick up truck on YT that get’s 50mpg with these things! No more gas or diesel fuel. (diesel’s were meant to run on cooking oil, they didn’t have diesel fuel when they were invented.) They are not very expensive to make though.

Looking for injectors for my 7790. Is there a part number to cross it over to that I could order from my part sto

I really appreciate the rebuild you did with your Diesel and the photos you posted.

What did you use to clean up your aluminum parts with?

My 7790 has been leaking fuel out of the top where the two lines go to the Injectors. Where can I get seals/gaskets to stop the leak? Also today it appears that It is only running on 1 cylinder – could that be due to the fuel leak.

I sent the aluminum heads in for rebuild at my local auto parts machine shop. They cleaned them with an acid wash but I am not sure what it was. I have no idea where to get engine parts for these anymore either. Kholer Engines bought out Lomberdini so you might have to give them a call. I made new copper gaskets for mine on my lathe and they worked great. Running on one cylinder means you either have a bad injector (or clogged) or the compression is too low in that cylinder to detonate the fuel. If you are leaking fuel really bad out the top of the fuel injector, that also could be why your cylinder is not firing.

I HAVE A 7790 FOR SALE CALL 7247620277

I asking 600 obo

Mike, love the article on the 7790.

Just acquired a 7790 for $350 and found your site on the rebuild.

Printed the operators manual and then realized that it’s only the even numbered pages.

Is there anyway to get a copy of the complete manual?

Hi Tom, Odd and even pages are there. The original manual is small only 1/2 of a normal page so when you print it, there are 2 manual pages on each printed page. I see the even numbers when I view the PDF file. Let me know if you still don’t see them.

Yep, your right they’re there.

Didn’t realize that they were half pages.

Thanks

TWhink I may have found a sister to this tractor friend has one in his shed and doesnt care for diesel work. But looks very close to the simplicity

Hello mike I have a 7790 and I was wondering how to hook up a Rototiller and what rototillers work for it

I have a 7790 I have bought books and I’m working on it. I’ve replaced all the motor mounts so far not with factory I’ve had to accommodate different isolators. I’m looking for an air filter. I cannot find a part number nowhere for it.